Features

Features

- ChillerTron automated fermentation control systems will improve your beer production time and repeatability, and reduce costly errors by providing remote access and text alarms for many common production problems.

- ChillerTron’s extremely stable temperature controls out-perform solenoids and have been fine-tuned over the last six years in dozens of breweries. ChillerTron continuously monitors your chiller performance, notifying you of common problems like process pump or compressor stoppage before it impacts your production.

- Our systems can help automate and monitor many aspects of Distilleries, Wineries, Cideries, and other industries where chillers play a key role in production success. Contact us today to find out how you can update your temperature control and remote process monitoring to the 21st century!

Proportional valve control(instead of solenoids)

using an adaptive PID control yields extremely stable fermentation temperature control which results in faster, more repeatable production

Remote Access

Remote Control and View through iPhone, iPad, Android and Windows

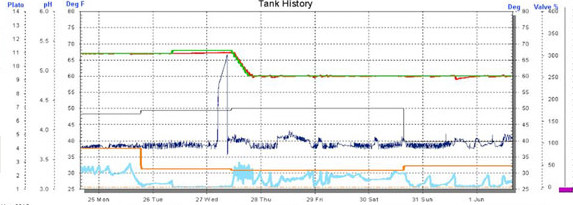

Continuous data logging

Logging and graphing of important brewing parameters for later analysis to support process improvement

Remote text messaging/emails for alarms

Yields peace of mind while you are away from the brewery that you will know if a major event threatens production

Dynamic Chiller Loading and Process Flow

Dynamic Chiller Loading manages the allocation of Chiller BTUs by priority among fermenters, crashing tanks, packaging/Brite tanks and Cold Liquor Tanks. ChillerTron automatically protects your active fermentation and reduces flow to lower priority loads like a cold liquor tank or crashing fermenters to make sure you have plenty of chilling power where you need it the most.

ChillerTron + Chiller Monitor protects your entire cooling system, not just your tanks

- Chiller Monitor integrates with your ChillerTron to monitor and display chiller

glycol temperature, pressure and flow on your control panel - Smart Temp Control: When high coolant demand causes a rise in glycol temperature, ChillerTron will turn off glycol flow if the coolant rises above beer temperature

- If demand continues to exceed chiller BTU capacity, available cooling will be allocated by priority

AutoCrash and Free Rise automate your post fermentation process

AutoCrash and Free Rise allow you to quickly and easily pick a date and time, a crash or rise temperature, and the number of hours for the process, and then automatically lowers or raises the setpoint every hour, stabilizing the load on the chiller, allowing diacetyl re-absorption, easily setting a dry hop temperature, and avoiding all the problems with trying to make sure someone remembers to keep changing all the various set points every hour.

Expandable to manage other aspects of brewery control and monitoring, and to more than 64 tanks

Grows with you! Ability to be quickly and easily expanded as new fermenters are added, and to monitor or control other equipment within the brewery such as walk-in temperatures, hot or cold liquor tanks, spent yeast and spent grain volume compliance reports, waste water temperature and pH, and report major equipment status such as air compressor and boilers. Our standard expansion kits control four tanks each and can be daisy chained to run an essentially unlimited number of tanks per base system.

Save money with reduced wiring, plumbing and maintenance costs

Compared to legacy panel meter and solenoid systems, ChillerTron has greatly reduced wiring requirements, with only one low voltage cable needed to run along the line of tanks. Because ChillerTron uses proportional valves, the main header sizing for coolant lines can be reduced over what would be required to support solenoids that open to full flow any time they are used. This saves installation material costs with less conduit and wires and smaller pipes, and saves on operation costs due to a reduced utility bill for circulating coolant. The metered action of the proportional valves also reduces the “water hammer” pressure effect compared to solenoids snapping open, thus extending the life of your coolant delivery lines.

Contact us

Contact us with any questions and ask us how we can simplify your brewing process, increase product and make better beer